CE certificate HD 2030BA-380 high pressure water jet laminated glass cutting machine

CE certificate HD 2030BA-380 high pressure water jet laminated glass cutting machine

| Payment Type: | L/C,T/T |

|---|---|

| Min. Order: | 1 Set/Sets |

| Delivery Time: | 30 Days |

| Packaging: | soft package |

|---|---|

| Brand: | HEAD |

| Place of Origin: | Liaoning, China (Mainland) |

| Supply Ability: | 20 Set/Sets per Month |

Basic Info

Model No.: HEAD2030BA/HD38030Z

Product Description

Specifications 1. American intensifier

2. can cut 100mm thickness

3.one time finish, no second processing

4. Professional software

water jet cutting machine technology Tap water is impressed to 200-400Mpa by UHP Intensifier, and then a waterjet with high speed of 800-1000m/s is made through a small gem nozzle with bore size of 0.1-0.35mm. This waterjet has high energy and it can cut soft materials such as Paper, rubber, sponge, etc. Furthermore, if mixed proper quantity abrasive, it can cut all kinds of soft and hard materials such as glass, marble, ceramics, stainless steel, etc The advantage for water jet laminated glass Cutting Machine Todary, the use of glass are more and more in all kinds of industries , one side promoting the development of glass industry, the other side, more diversified demands is put forward for the glass industry . Waterjet provides a quick and convenient to solve the casefor glass poducts,. Glass is fragile, adopts the mechanical cutting there will be a large amount of waste materials, and laser, plasma, etc. thermal cutting mode, manual cutting is low efficiency, difficult to cut curve cutting. 1. For the flat galss , any shapes can be cut by waterjet; 2. Cutting size accurate, beautiful, the kerf is grind arenaceous shape; 3. Cold cutting ,no heat ,no arc marks at the edge,safe,environmental protection ; 4. Can cut any shapes without mould ,easy to operate.

The advantage for water jet laminated glass Cutting Machine Todary, the use of glass are more and more in all kinds of industries , one side promoting the development of glass industry, the other side, more diversified demands is put forward for the glass industry . Waterjet provides a quick and convenient to solve the casefor glass poducts,. Glass is fragile, adopts the mechanical cutting there will be a large amount of waste materials, and laser, plasma, etc. thermal cutting mode, manual cutting is low efficiency, difficult to cut curve cutting. 1. For the flat galss , any shapes can be cut by waterjet; 2. Cutting size accurate, beautiful, the kerf is grind arenaceous shape; 3. Cold cutting ,no heat ,no arc marks at the edge,safe,environmental protection ; 4. Can cut any shapes without mould ,easy to operate.  Product Description The water jet cutting machine includes three main parts,the following is main charactors: 1.Cutting table: a.flying arm style,easy to load and unload material, b.separated body between cutting table and platform, c.X beam of cutting table applies the one-off extrusion forming aluminum alloy, d.Load-bearing beam with overall shield to avoid dust, e. flexible coupling of motor and ball screw, high qualiy ABBA ball screw and linear guide, f.use fluorocarbon coating, more than 20 years of corrosion resistance 2. Intensifier pump: a. Accustream brand intensifier import from the USA b. Electronic Direction Regulation c. 7-inch Touch Screen, Man-machine Interface Indicate Working Conditions error d. Maximum Flow of Hydraulic Pump: 90L/min e. Maximum Discharge Capacity: 3.7L/min f. Integrated heat exchanger, high heat exchange ratio and good effect g.Two-step up water supply h. Few wear parts in the intensifier,save the cost 3. CNC controller: a.19inch LCD b. Support DXF file ,can use AUTOCAD to produce DXF file c. use IPC and the professional software based on windows XP d. use Omron PLC instead of relay 4. The other accessories to improve the function

Product Description The water jet cutting machine includes three main parts,the following is main charactors: 1.Cutting table: a.flying arm style,easy to load and unload material, b.separated body between cutting table and platform, c.X beam of cutting table applies the one-off extrusion forming aluminum alloy, d.Load-bearing beam with overall shield to avoid dust, e. flexible coupling of motor and ball screw, high qualiy ABBA ball screw and linear guide, f.use fluorocarbon coating, more than 20 years of corrosion resistance 2. Intensifier pump: a. Accustream brand intensifier import from the USA b. Electronic Direction Regulation c. 7-inch Touch Screen, Man-machine Interface Indicate Working Conditions error d. Maximum Flow of Hydraulic Pump: 90L/min e. Maximum Discharge Capacity: 3.7L/min f. Integrated heat exchanger, high heat exchange ratio and good effect g.Two-step up water supply h. Few wear parts in the intensifier,save the cost 3. CNC controller: a.19inch LCD b. Support DXF file ,can use AUTOCAD to produce DXF file c. use IPC and the professional software based on windows XP d. use Omron PLC instead of relay 4. The other accessories to improve the function  5. Machine details display

5. Machine details display

6. Our qualification certificate

6. Our qualification certificate  Packaging & Shipping We use soft package and fixed tool to fix the machine in container

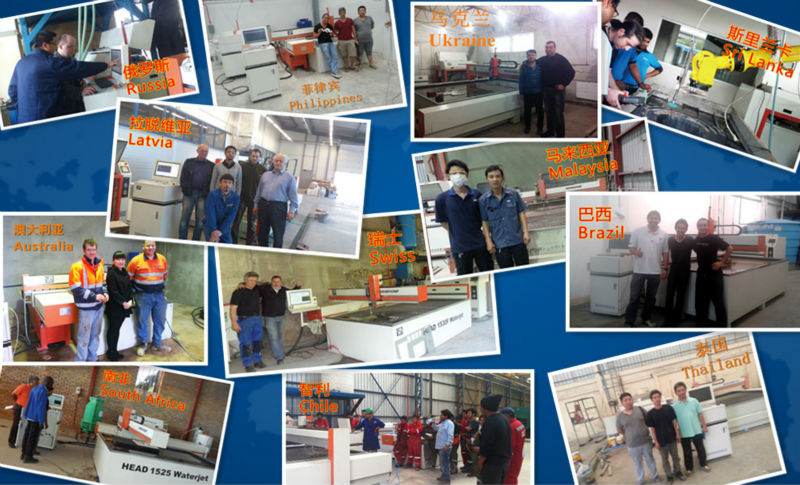

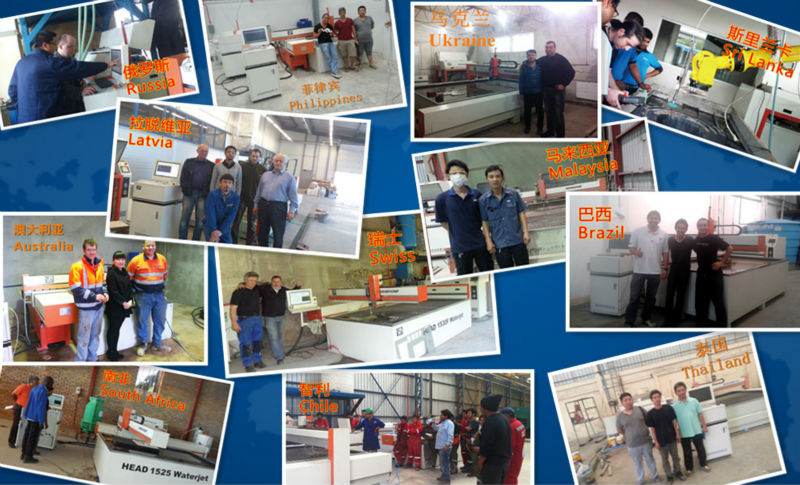

Packaging & Shipping We use soft package and fixed tool to fix the machine in container  Our Services We can send engineer to your factory to install the machine and do the training for your worker.

Our Services We can send engineer to your factory to install the machine and do the training for your worker.  FAQ 1. How to buy a water jet cutting macine? How can we choose the model? You only need to offer us the size of your materials, we will make the cutting table accordingly. 2. Is there thickness requirement for using the machine? For better cutting, we suggest you to cut cut materials within 100mm thickness. 3. What is the price item and payment way? We accept the T/T and L/C payment, 30% as deposit and 70% before delivery. 4. Is the machine have requirement for water quality? commom water from tap is ok 5. What is the type of the abrasive? Where can I find it? We often use 60 mesh and 80 mesh, we can help you to buy from China, or you may find from local market. 6. What is the chiller way? We use water cooling, and for very high temperature area, we can match with oil chiller for you. 7. What do we need to prepare before using the machine? We can send a preparation guide file before the machine arrive, you need to prepare water supply, power supply, air supply, cables, tubes, and necessary tools. 8. How long is the warranty time and what is the warranty item? For often it is one year, and we will give you a warranty item list 9. Do we need to buy spare parts from you if we need to change? We suggest you to buy from us, for it is original products. 10. If we meet troubleshooting of the machine, how can we solve it? You can send email or call us, and show your problem by photo or videos, and we will forward it to our service department, and will give you response within 24 hours. Contact us if you need more details on Laminated Glass Cutting Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Water Jet Laminated Glass Cutting Machine、High Pressure Water Jet Laminated Glass Cutting Machine Price. If these products fail to match your need, please contact us and we would like to provide relevant information.

FAQ 1. How to buy a water jet cutting macine? How can we choose the model? You only need to offer us the size of your materials, we will make the cutting table accordingly. 2. Is there thickness requirement for using the machine? For better cutting, we suggest you to cut cut materials within 100mm thickness. 3. What is the price item and payment way? We accept the T/T and L/C payment, 30% as deposit and 70% before delivery. 4. Is the machine have requirement for water quality? commom water from tap is ok 5. What is the type of the abrasive? Where can I find it? We often use 60 mesh and 80 mesh, we can help you to buy from China, or you may find from local market. 6. What is the chiller way? We use water cooling, and for very high temperature area, we can match with oil chiller for you. 7. What do we need to prepare before using the machine? We can send a preparation guide file before the machine arrive, you need to prepare water supply, power supply, air supply, cables, tubes, and necessary tools. 8. How long is the warranty time and what is the warranty item? For often it is one year, and we will give you a warranty item list 9. Do we need to buy spare parts from you if we need to change? We suggest you to buy from us, for it is original products. 10. If we meet troubleshooting of the machine, how can we solve it? You can send email or call us, and show your problem by photo or videos, and we will forward it to our service department, and will give you response within 24 hours. Contact us if you need more details on Laminated Glass Cutting Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Water Jet Laminated Glass Cutting Machine、High Pressure Water Jet Laminated Glass Cutting Machine Price. If these products fail to match your need, please contact us and we would like to provide relevant information.

2. can cut 100mm thickness

3.one time finish, no second processing

4. Professional software

water jet cutting machine technology Tap water is impressed to 200-400Mpa by UHP Intensifier, and then a waterjet with high speed of 800-1000m/s is made through a small gem nozzle with bore size of 0.1-0.35mm. This waterjet has high energy and it can cut soft materials such as Paper, rubber, sponge, etc. Furthermore, if mixed proper quantity abrasive, it can cut all kinds of soft and hard materials such as glass, marble, ceramics, stainless steel, etc

The advantage for water jet laminated glass Cutting Machine Todary, the use of glass are more and more in all kinds of industries , one side promoting the development of glass industry, the other side, more diversified demands is put forward for the glass industry . Waterjet provides a quick and convenient to solve the casefor glass poducts,. Glass is fragile, adopts the mechanical cutting there will be a large amount of waste materials, and laser, plasma, etc. thermal cutting mode, manual cutting is low efficiency, difficult to cut curve cutting. 1. For the flat galss , any shapes can be cut by waterjet; 2. Cutting size accurate, beautiful, the kerf is grind arenaceous shape; 3. Cold cutting ,no heat ,no arc marks at the edge,safe,environmental protection ; 4. Can cut any shapes without mould ,easy to operate.

The advantage for water jet laminated glass Cutting Machine Todary, the use of glass are more and more in all kinds of industries , one side promoting the development of glass industry, the other side, more diversified demands is put forward for the glass industry . Waterjet provides a quick and convenient to solve the casefor glass poducts,. Glass is fragile, adopts the mechanical cutting there will be a large amount of waste materials, and laser, plasma, etc. thermal cutting mode, manual cutting is low efficiency, difficult to cut curve cutting. 1. For the flat galss , any shapes can be cut by waterjet; 2. Cutting size accurate, beautiful, the kerf is grind arenaceous shape; 3. Cold cutting ,no heat ,no arc marks at the edge,safe,environmental protection ; 4. Can cut any shapes without mould ,easy to operate.  Product Description The water jet cutting machine includes three main parts,the following is main charactors: 1.Cutting table: a.flying arm style,easy to load and unload material, b.separated body between cutting table and platform, c.X beam of cutting table applies the one-off extrusion forming aluminum alloy, d.Load-bearing beam with overall shield to avoid dust, e. flexible coupling of motor and ball screw, high qualiy ABBA ball screw and linear guide, f.use fluorocarbon coating, more than 20 years of corrosion resistance 2. Intensifier pump: a. Accustream brand intensifier import from the USA b. Electronic Direction Regulation c. 7-inch Touch Screen, Man-machine Interface Indicate Working Conditions error d. Maximum Flow of Hydraulic Pump: 90L/min e. Maximum Discharge Capacity: 3.7L/min f. Integrated heat exchanger, high heat exchange ratio and good effect g.Two-step up water supply h. Few wear parts in the intensifier,save the cost 3. CNC controller: a.19inch LCD b. Support DXF file ,can use AUTOCAD to produce DXF file c. use IPC and the professional software based on windows XP d. use Omron PLC instead of relay 4. The other accessories to improve the function

Product Description The water jet cutting machine includes three main parts,the following is main charactors: 1.Cutting table: a.flying arm style,easy to load and unload material, b.separated body between cutting table and platform, c.X beam of cutting table applies the one-off extrusion forming aluminum alloy, d.Load-bearing beam with overall shield to avoid dust, e. flexible coupling of motor and ball screw, high qualiy ABBA ball screw and linear guide, f.use fluorocarbon coating, more than 20 years of corrosion resistance 2. Intensifier pump: a. Accustream brand intensifier import from the USA b. Electronic Direction Regulation c. 7-inch Touch Screen, Man-machine Interface Indicate Working Conditions error d. Maximum Flow of Hydraulic Pump: 90L/min e. Maximum Discharge Capacity: 3.7L/min f. Integrated heat exchanger, high heat exchange ratio and good effect g.Two-step up water supply h. Few wear parts in the intensifier,save the cost 3. CNC controller: a.19inch LCD b. Support DXF file ,can use AUTOCAD to produce DXF file c. use IPC and the professional software based on windows XP d. use Omron PLC instead of relay 4. The other accessories to improve the function  5. Machine details display

5. Machine details display

6. Our qualification certificate

6. Our qualification certificate  Packaging & Shipping We use soft package and fixed tool to fix the machine in container

Packaging & Shipping We use soft package and fixed tool to fix the machine in container  Our Services We can send engineer to your factory to install the machine and do the training for your worker.

Our Services We can send engineer to your factory to install the machine and do the training for your worker.  FAQ 1. How to buy a water jet cutting macine? How can we choose the model? You only need to offer us the size of your materials, we will make the cutting table accordingly. 2. Is there thickness requirement for using the machine? For better cutting, we suggest you to cut cut materials within 100mm thickness. 3. What is the price item and payment way? We accept the T/T and L/C payment, 30% as deposit and 70% before delivery. 4. Is the machine have requirement for water quality? commom water from tap is ok 5. What is the type of the abrasive? Where can I find it? We often use 60 mesh and 80 mesh, we can help you to buy from China, or you may find from local market. 6. What is the chiller way? We use water cooling, and for very high temperature area, we can match with oil chiller for you. 7. What do we need to prepare before using the machine? We can send a preparation guide file before the machine arrive, you need to prepare water supply, power supply, air supply, cables, tubes, and necessary tools. 8. How long is the warranty time and what is the warranty item? For often it is one year, and we will give you a warranty item list 9. Do we need to buy spare parts from you if we need to change? We suggest you to buy from us, for it is original products. 10. If we meet troubleshooting of the machine, how can we solve it? You can send email or call us, and show your problem by photo or videos, and we will forward it to our service department, and will give you response within 24 hours. Contact us if you need more details on Laminated Glass Cutting Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Water Jet Laminated Glass Cutting Machine、High Pressure Water Jet Laminated Glass Cutting Machine Price. If these products fail to match your need, please contact us and we would like to provide relevant information.

FAQ 1. How to buy a water jet cutting macine? How can we choose the model? You only need to offer us the size of your materials, we will make the cutting table accordingly. 2. Is there thickness requirement for using the machine? For better cutting, we suggest you to cut cut materials within 100mm thickness. 3. What is the price item and payment way? We accept the T/T and L/C payment, 30% as deposit and 70% before delivery. 4. Is the machine have requirement for water quality? commom water from tap is ok 5. What is the type of the abrasive? Where can I find it? We often use 60 mesh and 80 mesh, we can help you to buy from China, or you may find from local market. 6. What is the chiller way? We use water cooling, and for very high temperature area, we can match with oil chiller for you. 7. What do we need to prepare before using the machine? We can send a preparation guide file before the machine arrive, you need to prepare water supply, power supply, air supply, cables, tubes, and necessary tools. 8. How long is the warranty time and what is the warranty item? For often it is one year, and we will give you a warranty item list 9. Do we need to buy spare parts from you if we need to change? We suggest you to buy from us, for it is original products. 10. If we meet troubleshooting of the machine, how can we solve it? You can send email or call us, and show your problem by photo or videos, and we will forward it to our service department, and will give you response within 24 hours. Contact us if you need more details on Laminated Glass Cutting Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Water Jet Laminated Glass Cutting Machine、High Pressure Water Jet Laminated Glass Cutting Machine Price. If these products fail to match your need, please contact us and we would like to provide relevant information. Product Categories : Water Jet Glass Cutting Machine

Premium Related Products

Other Products

Hot Products

Rotary Packing Machine for FoodRoll Feeding Square Bottom Paper Hand Bag Machine1050 Flexo Paper Cup Printing MachinePaper Cup Printing Machine, PE Coated Paper1000*2000mm good price ultra-high pressure rubber cutting machinewater jet cutting machine with 3000mm*2000mm cutting table and 380Mpa intensifier pumpManufacturer water jet cutting pump intensifier pumpfor cutting composite material 1500*3000mm by CNC high pressureCE glass CNC water jet cutteraluminum cutting aluminium cutter machine aluminium sheet cutting machineCE certificate CNC waterjet glass cutting machine /waterjet cutter for glasscnc glass cutting machine price glass waterjetCNC marble mosaic cutting machine with competitive price tile cutting machine1500*2500mm cnc cantilever type marble and ceramic tile medallion waterjet cutting machine1500*2500mm cnc cantilever type stone cutting machine1500*2500mm portable water jet cutting machine for gas tube