marble and granite cutting waterjet machine granite&granite cutting water jet machine

marble and granite cutting waterjet machine granite&granite cutting water jet machine

| Payment Type: | L/C,T/T |

|---|---|

| Min. Order: | 1 Set/Sets |

| Delivery Time: | 30 Days |

| Packaging: | marble cutting machine granite waterjet cutting is packed by 20\" container |

|---|---|

| Brand: | HEAD |

| Place of Origin: | Liaoning, China (Mainland) |

| Supply Ability: | 20 Set/Sets per Month marble cutting machine granite waterjet cutting is 1 set |

Basic Info

Model No.: HEAD3020BA/HEAD42037Z

Product Description

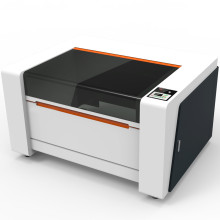

Product Description HEAD waterjet Cutting Machine is the best choice for marble cutting, our team has rich experience on this filed, we are confident we will suppy you the best solution. Processing product samples

Waterjet cutting machine introduction: Tap water is impressed to 200-400Mpa by UHP Intensifier, and then a waterjet with high speed of 800-1000m/s is made through a small gem nozzle with bore size of 0.1-0.35mm. This waterjet has high energy and it can cut soft materials such as Paper, rubber, sponge, etc. Furthermore, if mixed proper quantity abrasive, it can cut all kinds of soft and hard materials such as glass, marble, ceramics, stainless steel, etc. TECHNICAL DATA

Waterjet cutting machine introduction: Tap water is impressed to 200-400Mpa by UHP Intensifier, and then a waterjet with high speed of 800-1000m/s is made through a small gem nozzle with bore size of 0.1-0.35mm. This waterjet has high energy and it can cut soft materials such as Paper, rubber, sponge, etc. Furthermore, if mixed proper quantity abrasive, it can cut all kinds of soft and hard materials such as glass, marble, ceramics, stainless steel, etc. TECHNICAL DATA

Quality Control Quality Control To ensure high quality machine, our engineers will check every machine quality before delivery. Engineer is responsible for his checking machine quality. ONE MACHINE FOR ONE ENGINNER ONE: UHP pump testing: 1.every intensifier pump will be tested by our engineers including ultra high pressure stable, continuous pressure time etc. 2. Servo motor data adjustment to ensure machine to operate perfectly in our customer factory. TWO: Cutting table accuracy testing: 1. every detail including loadbearing table,liner guide accuracy etc will be checked by our engineers. 2. We introduced laser interferometer to ensure cutting table high accuracy. Every machine will be strictly tested by our works and engineers before delivery. Quality control device,we use different inspection device to test device during diffirent processing procedure.  Advantage of marble waterjet cutting machine 1.Cold cutting without thermal influences. 2.Flexible processing of virtually all materials with consistent high quality. 3..Material-saving production due to reduced cutting width and the nesting of several parts on a single sheet. 4.Maximum degree of material utilization due to the smallest of part separation distances (partially free of burrs) and part-in-part production. 5.Tension-free processed parts due to minimal cutting force. For the griotte cutting, we recommand our floor-type loading system. The cutting table adapts latest loading design, the max overturn angle is 85,the distance between loading material and ground is only 100mm,max loadearing is 1000KG ,hydraulic lifting and some other designs can meet the requirement of marble cutting .The situation many personnels are needed for loading material is changed , nowadays only 1 person is needed for the whole loading process .simple,convenient ,greatly reduce the labor cost and minium the marble breakage.This cutting table structure is 1st time adapted in domestic.It gains high praise once used by lots of marble processing clients.

Advantage of marble waterjet cutting machine 1.Cold cutting without thermal influences. 2.Flexible processing of virtually all materials with consistent high quality. 3..Material-saving production due to reduced cutting width and the nesting of several parts on a single sheet. 4.Maximum degree of material utilization due to the smallest of part separation distances (partially free of burrs) and part-in-part production. 5.Tension-free processed parts due to minimal cutting force. For the griotte cutting, we recommand our floor-type loading system. The cutting table adapts latest loading design, the max overturn angle is 85,the distance between loading material and ground is only 100mm,max loadearing is 1000KG ,hydraulic lifting and some other designs can meet the requirement of marble cutting .The situation many personnels are needed for loading material is changed , nowadays only 1 person is needed for the whole loading process .simple,convenient ,greatly reduce the labor cost and minium the marble breakage.This cutting table structure is 1st time adapted in domestic.It gains high praise once used by lots of marble processing clients.  Packaging & Shipping marble waterjet cutting machine will be packed by Soft package in 20 feet container by FCL

Packaging & Shipping marble waterjet cutting machine will be packed by Soft package in 20 feet container by FCL  Our Services

Our Services  Overseas service is avaiable. Our engineers will help you install and commision in your factory. 7 days per week, 24 hours per day, We are all here for you. Technical Training: 1. UHP Intensifier principle 2. Introduction of every parts 3. Wear parts replacement 4. Elimination of normal troubles 5. Table maintenance 6. On-off valve, cutting head and abrasive controller maintenance. 7. Drawing designing and programming 8. Software operating, parameters setting and saving 9. Equipment operating Any place, any time, you need us, our after-sales service will be there. Certificate

Overseas service is avaiable. Our engineers will help you install and commision in your factory. 7 days per week, 24 hours per day, We are all here for you. Technical Training: 1. UHP Intensifier principle 2. Introduction of every parts 3. Wear parts replacement 4. Elimination of normal troubles 5. Table maintenance 6. On-off valve, cutting head and abrasive controller maintenance. 7. Drawing designing and programming 8. Software operating, parameters setting and saving 9. Equipment operating Any place, any time, you need us, our after-sales service will be there. Certificate  FAQ WHY CHOOSE US? 1. High quality The components we use is from high level suppliers, which can guarantee the stable working and long life use time. The no troubleshorting working time can be over 1000 hours Can guarantee the cutting accuracy 2. Easy operation Professional Water Cutting Machine software, no need G code program, you only need to know the use of AUTOCAD 3. New function development We work to develop new products to update the function of machine, for short time, we reserch the loading system, height tracking system, wireless handle, four-axis cutting head. 4. Favorable spare parts price and supply on time. When your machine need spare parts to work, we will act quickly, and guarantte the machine work continuously. 5. After sale service Professional service team and 24 hours online to solve your problems, give quick and professional guide. Contact us if you need more details on Marble and Granite Cutting Waterjet Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Granite&granite Cutting Water Jet Machine、Waterjet Machine Granite and Granite Cutting. If these products fail to match your need, please contact us and we would like to provide relevant information.

FAQ WHY CHOOSE US? 1. High quality The components we use is from high level suppliers, which can guarantee the stable working and long life use time. The no troubleshorting working time can be over 1000 hours Can guarantee the cutting accuracy 2. Easy operation Professional Water Cutting Machine software, no need G code program, you only need to know the use of AUTOCAD 3. New function development We work to develop new products to update the function of machine, for short time, we reserch the loading system, height tracking system, wireless handle, four-axis cutting head. 4. Favorable spare parts price and supply on time. When your machine need spare parts to work, we will act quickly, and guarantte the machine work continuously. 5. After sale service Professional service team and 24 hours online to solve your problems, give quick and professional guide. Contact us if you need more details on Marble and Granite Cutting Waterjet Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Granite&granite Cutting Water Jet Machine、Waterjet Machine Granite and Granite Cutting. If these products fail to match your need, please contact us and we would like to provide relevant information.

Waterjet cutting machine introduction: Tap water is impressed to 200-400Mpa by UHP Intensifier, and then a waterjet with high speed of 800-1000m/s is made through a small gem nozzle with bore size of 0.1-0.35mm. This waterjet has high energy and it can cut soft materials such as Paper, rubber, sponge, etc. Furthermore, if mixed proper quantity abrasive, it can cut all kinds of soft and hard materials such as glass, marble, ceramics, stainless steel, etc. TECHNICAL DATA

Waterjet cutting machine introduction: Tap water is impressed to 200-400Mpa by UHP Intensifier, and then a waterjet with high speed of 800-1000m/s is made through a small gem nozzle with bore size of 0.1-0.35mm. This waterjet has high energy and it can cut soft materials such as Paper, rubber, sponge, etc. Furthermore, if mixed proper quantity abrasive, it can cut all kinds of soft and hard materials such as glass, marble, ceramics, stainless steel, etc. TECHNICAL DATA | Model | HEAD42037Z |

| Brand | from USA |

| Method of Direction Regulation | Electronic Direction Regulation |

| Pressure Range | 300-420MPA |

| Maximum Flow of Hydraulic Pump | 106L/min |

| Maximum Discharge Capacity | 3.8L/min |

| Maximum Diameter of Gem Nozzle | 0.33mm |

| Power of Master Motor | 37KW(50Hp) |

| Power Source | 380V/50HZ |

| X axis characteristic | One-off extrusion forming aluminum alloy |

| Y axis characteristic | Cast iron used as foundation base |

| Z axis characteristic | double linear guide and four sliding block |

| Driving system | Z axis automatic controll,3axis association process |

| Ball screw,linear guide | ABBA Taiwan |

| Table structure | Separated body |

| Driving way | Servo drive system |

| CNC system | Ncstudio ,Fagor |

| Servo motor | YASKAWA/FUJI |

| Cutting head | Casting structure and concrete structure |

| Sealing way | Whole piece sealing |

| Loading weight water tank | Wall thickness is 5mm,using fluorocarbon coating |

| Control Method | CNC |

| Display Size | 19inch LCD |

| Model of Cutting Text | DXF |

| Model of Computer | Industrial Control Computer |

| Operating System | Windows XP/7 |

| PLC | OMRON |

| Cutting software advantage | Auto save and transfer common parameter |

| Controller displace | Can be fit to suitable place at own will |

| Founction | Sand storage and sand delivery |

| Operating | No need electrocnic control,sample operation |

| Capacity | 200 liters for 8 hours |

| Pressure | Less than 0.2Mpa compresses gas pressure |

| Level | Standard equipment of HEAD waterjet |

| It can supply the sand quantity according to the adjustable sand level location tube in the sand bin, without any electrical connect units,more safe and reliable . | |

| Founction | Softening water |

| Operation | Simple operation |

| advantage | Inmproving useful life of other parts |

Groundwater,minerals contained is very high, will cause the problem of cutting accuracy after long time using. | |

| Founction | Wireless controlling waterjet |

| Display | Real- time display condition of X,Y,Z axis |

| Settings | Zero point, on/off valve set, X,Y,Z axis moving |

| Technology | Advanced technology |

| Special designed for HEAD water jet control system, it could realise wireless controling water jet and it can control long-distance material processing,improving work efficiency. | |

Advantage of marble waterjet cutting machine 1.Cold cutting without thermal influences. 2.Flexible processing of virtually all materials with consistent high quality. 3..Material-saving production due to reduced cutting width and the nesting of several parts on a single sheet. 4.Maximum degree of material utilization due to the smallest of part separation distances (partially free of burrs) and part-in-part production. 5.Tension-free processed parts due to minimal cutting force. For the griotte cutting, we recommand our floor-type loading system. The cutting table adapts latest loading design, the max overturn angle is 85,the distance between loading material and ground is only 100mm,max loadearing is 1000KG ,hydraulic lifting and some other designs can meet the requirement of marble cutting .The situation many personnels are needed for loading material is changed , nowadays only 1 person is needed for the whole loading process .simple,convenient ,greatly reduce the labor cost and minium the marble breakage.This cutting table structure is 1st time adapted in domestic.It gains high praise once used by lots of marble processing clients.

Advantage of marble waterjet cutting machine 1.Cold cutting without thermal influences. 2.Flexible processing of virtually all materials with consistent high quality. 3..Material-saving production due to reduced cutting width and the nesting of several parts on a single sheet. 4.Maximum degree of material utilization due to the smallest of part separation distances (partially free of burrs) and part-in-part production. 5.Tension-free processed parts due to minimal cutting force. For the griotte cutting, we recommand our floor-type loading system. The cutting table adapts latest loading design, the max overturn angle is 85,the distance between loading material and ground is only 100mm,max loadearing is 1000KG ,hydraulic lifting and some other designs can meet the requirement of marble cutting .The situation many personnels are needed for loading material is changed , nowadays only 1 person is needed for the whole loading process .simple,convenient ,greatly reduce the labor cost and minium the marble breakage.This cutting table structure is 1st time adapted in domestic.It gains high praise once used by lots of marble processing clients.  Packaging & Shipping marble waterjet cutting machine will be packed by Soft package in 20 feet container by FCL

Packaging & Shipping marble waterjet cutting machine will be packed by Soft package in 20 feet container by FCL  Our Services

Our Services  Overseas service is avaiable. Our engineers will help you install and commision in your factory. 7 days per week, 24 hours per day, We are all here for you. Technical Training: 1. UHP Intensifier principle 2. Introduction of every parts 3. Wear parts replacement 4. Elimination of normal troubles 5. Table maintenance 6. On-off valve, cutting head and abrasive controller maintenance. 7. Drawing designing and programming 8. Software operating, parameters setting and saving 9. Equipment operating Any place, any time, you need us, our after-sales service will be there. Certificate

Overseas service is avaiable. Our engineers will help you install and commision in your factory. 7 days per week, 24 hours per day, We are all here for you. Technical Training: 1. UHP Intensifier principle 2. Introduction of every parts 3. Wear parts replacement 4. Elimination of normal troubles 5. Table maintenance 6. On-off valve, cutting head and abrasive controller maintenance. 7. Drawing designing and programming 8. Software operating, parameters setting and saving 9. Equipment operating Any place, any time, you need us, our after-sales service will be there. Certificate  FAQ WHY CHOOSE US? 1. High quality The components we use is from high level suppliers, which can guarantee the stable working and long life use time. The no troubleshorting working time can be over 1000 hours Can guarantee the cutting accuracy 2. Easy operation Professional Water Cutting Machine software, no need G code program, you only need to know the use of AUTOCAD 3. New function development We work to develop new products to update the function of machine, for short time, we reserch the loading system, height tracking system, wireless handle, four-axis cutting head. 4. Favorable spare parts price and supply on time. When your machine need spare parts to work, we will act quickly, and guarantte the machine work continuously. 5. After sale service Professional service team and 24 hours online to solve your problems, give quick and professional guide. Contact us if you need more details on Marble and Granite Cutting Waterjet Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Granite&granite Cutting Water Jet Machine、Waterjet Machine Granite and Granite Cutting. If these products fail to match your need, please contact us and we would like to provide relevant information.

FAQ WHY CHOOSE US? 1. High quality The components we use is from high level suppliers, which can guarantee the stable working and long life use time. The no troubleshorting working time can be over 1000 hours Can guarantee the cutting accuracy 2. Easy operation Professional Water Cutting Machine software, no need G code program, you only need to know the use of AUTOCAD 3. New function development We work to develop new products to update the function of machine, for short time, we reserch the loading system, height tracking system, wireless handle, four-axis cutting head. 4. Favorable spare parts price and supply on time. When your machine need spare parts to work, we will act quickly, and guarantte the machine work continuously. 5. After sale service Professional service team and 24 hours online to solve your problems, give quick and professional guide. Contact us if you need more details on Marble and Granite Cutting Waterjet Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Granite&granite Cutting Water Jet Machine、Waterjet Machine Granite and Granite Cutting. If these products fail to match your need, please contact us and we would like to provide relevant information. Product Categories : Stone And Marble Cutting Machine

Premium Related Products

Other Products

Hot Products

Rotary Packing Machine for FoodRoll Feeding Square Bottom Paper Hand Bag Machine1050 Flexo Paper Cup Printing MachinePaper Cup Printing Machine, PE Coated Paper1000*2000mm good price ultra-high pressure rubber cutting machinewater jet cutting machine with 3000mm*2000mm cutting table and 380Mpa intensifier pumpManufacturer water jet cutting pump intensifier pumpfor cutting composite material 1500*3000mm by CNC high pressureCE glass CNC water jet cutteraluminum cutting aluminium cutter machine aluminium sheet cutting machineCE certificate CNC waterjet glass cutting machine /waterjet cutter for glasscnc glass cutting machine price glass waterjetCNC marble mosaic cutting machine with competitive price tile cutting machine1500*2500mm cnc cantilever type marble and ceramic tile medallion waterjet cutting machine1500*2500mm cnc cantilever type stone cutting machine1500*2500mm portable water jet cutting machine for gas tube