2000mm*4000mm cooling cutting waterjet glass cutting machines

2000mm*4000mm cooling cutting waterjet glass cutting machines

| Payment Type: | L/C,T/T |

|---|---|

| Min. Order: | 1 Set/Sets |

| Delivery Time: | 30 Days |

| Packaging: | Soft package or as your request in 20/40 feet container |

|---|---|

| Brand: | HEAD |

| Place of Origin: | Liaoning, China (Mainland) |

| Supply Ability: | 15 Set/Sets per Month waterjet glass cutting machines |

Basic Info

Model No.: HEAD2040BA/HEAD38030Z

Product Description

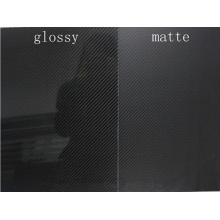

Product Description Glass Cutting with Waterjet Abrasive waterjet cutting technology is a great method for cutting glass because it allows for contours and shapes that cannot be achieved with other cutting machines at a reasonable cost. From artistic tabletop inlays to detailed stained glass designs, mirrors, glass ornaments, replacement windows for antique cars, and more, there’s almost no glass cutting application that a waterjet Cutting Machine from China HEAD Waterjet can’t tackle. Glass has a tendency to crack, so it is very important that the initial holes are produced with a reduced pressure of 2000-4200 bar. Subsequently, the pressure must be increased to a cutting speed that is cost-effective. For glass, ceramics and other brittle materials, you must gradually increase and reduce the cutting pressure by means of proportional pressure control of the intensifier pump, otherwise the material would be destroyed. As an alternative to quartz sand, olivine can be used as an abrasive because it is softer, which reduces the potential for chipping, cracking and other surface blemishes and leaves a cut edge that is polished to a smooth finish. Because water jet cutting does not vibrate the glass, there is no heat-affected zones (HAZ), or leave behind rough edges, almost no secondary finishing is required. HEAD water jet machine price glass Cutter Machine Glass cutting samples

Detailed information of HEAD Water Jet Cutting Machine just for you !

Detailed information of HEAD Water Jet Cutting Machine just for you !

Our best partners who could guarantee the KEY components ! ! ! QC To ensure the quality,we make a lot of test on quality control. 1.The strict inspection process before delivery from factory. 2.Professional adjustment to guarantee the accuracy. 3.Intensifier pump stability inspection.

QC To ensure the quality,we make a lot of test on quality control. 1.The strict inspection process before delivery from factory. 2.Professional adjustment to guarantee the accuracy. 3.Intensifier pump stability inspection.  Packaging & Shipping Soft package in 20 or 40 feet container by FCL

Packaging & Shipping Soft package in 20 or 40 feet container by FCL  Our Services "One to One" exclusive service : HEAD provides technical and maintenance support ,make you master water jet operation Instant response : HEAD water jet after-sale will reply and solve within 2 hours after receivingyour problem Spare parts green channel : HEAD provides high quality accessories,supplies and services to you .

Our Services "One to One" exclusive service : HEAD provides technical and maintenance support ,make you master water jet operation Instant response : HEAD water jet after-sale will reply and solve within 2 hours after receivingyour problem Spare parts green channel : HEAD provides high quality accessories,supplies and services to you .  Company Information As concentrated So professional HEAD has specialized in designing,manufacturingl water jet machine,HEAD water jet machine will make the water jet machine field much more abundant,Our craftmanship water jet machine has been in the international leading level,we sincerely hope to creat and share success with you . "Teamwork,Diligent,Realistic,Creative" our consistent business principle.with our rich experience and considerate services,we have been recognised as a realiable water jet machine supplier among the international buyers. HEAD has a strong research and development,production sales and service team,shenyang HEAD science and technology co.ltd has gradually become well-known enterprises in water jet field.

Company Information As concentrated So professional HEAD has specialized in designing,manufacturingl water jet machine,HEAD water jet machine will make the water jet machine field much more abundant,Our craftmanship water jet machine has been in the international leading level,we sincerely hope to creat and share success with you . "Teamwork,Diligent,Realistic,Creative" our consistent business principle.with our rich experience and considerate services,we have been recognised as a realiable water jet machine supplier among the international buyers. HEAD has a strong research and development,production sales and service team,shenyang HEAD science and technology co.ltd has gradually become well-known enterprises in water jet field.  ADVANTAGES OF CUTTING GLASS WITH WATERJET • Cut glass geometry that common machining cannot perform

ADVANTAGES OF CUTTING GLASS WITH WATERJET • Cut glass geometry that common machining cannot perform

• Delicate glass does not crack during processing

• Precisely cut thin to thick glass without changing any tooling

• Cuts glass panels up to 100MM in thickness

• Eliminates pressure of cutting process on surface material

• No heat affected zone (HAZ)

• No tool to sharpen

• No or reduced need for reworking of the cut edge

• No waste of material, narrow cutting gap

• Cost effective means of cutting holes in glass

• Create intricate design in any shape and size

(Not suitable for the processing of tempered or hot glass) Everyday Uses

• Tabletop inlay

• Flat glass with numerous contours

• Stained glass

• Church mosaics

• Light fixtures

• Frameless shower screens

• Bullet-proof glass

• Mirrors

• Kitchen and bathroom splash backs

• Laminated glass

• Window panels

• Lenses

• Glass components for electronic & medical industry

• Optical laser parts

• Replacement glass for antique autos

• Glass ornaments Contact us if you need more details on Waterjet Glass Cutting Machines. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Water Cut Glass Machine、Waterjet Glass Cutting Machines. If these products fail to match your need, please contact us and we would like to provide relevant information.

Contact us if you need more details on Waterjet Glass Cutting Machines. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Water Cut Glass Machine、Waterjet Glass Cutting Machines. If these products fail to match your need, please contact us and we would like to provide relevant information.

Detailed information of HEAD Water Jet Cutting Machine just for you !

Detailed information of HEAD Water Jet Cutting Machine just for you ! | Model | HD38030Z |

| Brand | Imported from USA |

| Method of Direction Regulation | Electronic Direction Regulation |

| Pressure Range | 330-3500MPA |

| Maximum Flow of Hydraulic Pump | 90L/min |

| Maximum Discharge Capacity | 3.7L/min, |

| Maximum Diameter of Gem Nozzle | 0.33mm |

| Power of Master Motor | 30KW(50Hp) |

| Power Source | 380V/50HZ |

| X axis characteristic | One-off extrusion forming aluminum alloy |

| Y axis characteristic | Cast iron used as foundation base |

| Z axis characteristic | double linear guide and four sliding block |

| Driving system | Z axis automatic controll,3axis association process |

| Ball screw,linear guide | ABBA Taiwan |

| Table structure | Separated body |

| Driving way | Servo drive system |

| CNC system | Ncstudio ,Fagor |

| Servo motor | YASKAWA/FUJI |

| Cutting head | Casting structure and concrete structure |

| Sealing way | Whole piece sealing |

| Loading weight water tank | Wall thickness is 5mm,using fluorocarbon coating |

| Control Method | CNC |

| Display Size | 19inch LCD |

| Model of Cutting Text | DXF |

| Model of Computer | Industrial Control Computer |

| Operating System | Windows XP/7 |

| PLC | OMRON |

| Cutting software advantage | Auto save and transfer common parameter |

| Controller displace | Can be fit to suitable place at own will |

| Founction | Sand storage and sand delivery |

| Operating | No need electrocnic control,sample operation |

| Capacity | 200 liters for 8 hours |

| Pressure | Less than 0.2Mpa compresses gas pressure |

| Level | Standard equipment of HEAD waterjet |

| It can supply the sand quantity according to the adjustable sand level location tube in the sand bin, without any electrical connect units,more safe and reliable . | |

| Founction | Softening water |

| Operation | Simple operation |

| advantage | Inmproving useful life of other parts |

| Groundwater,minerals contained is very high, will cause the problem of cutting accuracy after long time using. | |

| Founction | Wireless controlling waterjet |

| Display | Real- time display condition of X,Y,Z axis |

| Settings | Zero point, on/off valve set, X,Y,Z axis moving |

| Technology | Advanced technology |

| Special designed for HEAD water jet control system, it could realise wireless controling water jet and it can control long-distance material processing,improving work efficiency. | |

Our best partners who could guarantee the KEY components ! ! !

QC To ensure the quality,we make a lot of test on quality control. 1.The strict inspection process before delivery from factory. 2.Professional adjustment to guarantee the accuracy. 3.Intensifier pump stability inspection.

QC To ensure the quality,we make a lot of test on quality control. 1.The strict inspection process before delivery from factory. 2.Professional adjustment to guarantee the accuracy. 3.Intensifier pump stability inspection.  Packaging & Shipping Soft package in 20 or 40 feet container by FCL

Packaging & Shipping Soft package in 20 or 40 feet container by FCL  Our Services "One to One" exclusive service : HEAD provides technical and maintenance support ,make you master water jet operation Instant response : HEAD water jet after-sale will reply and solve within 2 hours after receivingyour problem Spare parts green channel : HEAD provides high quality accessories,supplies and services to you .

Our Services "One to One" exclusive service : HEAD provides technical and maintenance support ,make you master water jet operation Instant response : HEAD water jet after-sale will reply and solve within 2 hours after receivingyour problem Spare parts green channel : HEAD provides high quality accessories,supplies and services to you .  Company Information As concentrated So professional HEAD has specialized in designing,manufacturingl water jet machine,HEAD water jet machine will make the water jet machine field much more abundant,Our craftmanship water jet machine has been in the international leading level,we sincerely hope to creat and share success with you . "Teamwork,Diligent,Realistic,Creative" our consistent business principle.with our rich experience and considerate services,we have been recognised as a realiable water jet machine supplier among the international buyers. HEAD has a strong research and development,production sales and service team,shenyang HEAD science and technology co.ltd has gradually become well-known enterprises in water jet field.

Company Information As concentrated So professional HEAD has specialized in designing,manufacturingl water jet machine,HEAD water jet machine will make the water jet machine field much more abundant,Our craftmanship water jet machine has been in the international leading level,we sincerely hope to creat and share success with you . "Teamwork,Diligent,Realistic,Creative" our consistent business principle.with our rich experience and considerate services,we have been recognised as a realiable water jet machine supplier among the international buyers. HEAD has a strong research and development,production sales and service team,shenyang HEAD science and technology co.ltd has gradually become well-known enterprises in water jet field.  ADVANTAGES OF CUTTING GLASS WITH WATERJET • Cut glass geometry that common machining cannot perform

ADVANTAGES OF CUTTING GLASS WITH WATERJET • Cut glass geometry that common machining cannot perform• Delicate glass does not crack during processing

• Precisely cut thin to thick glass without changing any tooling

• Cuts glass panels up to 100MM in thickness

• Eliminates pressure of cutting process on surface material

• No heat affected zone (HAZ)

• No tool to sharpen

• No or reduced need for reworking of the cut edge

• No waste of material, narrow cutting gap

• Cost effective means of cutting holes in glass

• Create intricate design in any shape and size

(Not suitable for the processing of tempered or hot glass) Everyday Uses

• Tabletop inlay

• Flat glass with numerous contours

• Stained glass

• Church mosaics

• Light fixtures

• Frameless shower screens

• Bullet-proof glass

• Mirrors

• Kitchen and bathroom splash backs

• Laminated glass

• Window panels

• Lenses

• Glass components for electronic & medical industry

• Optical laser parts

• Replacement glass for antique autos

• Glass ornaments

Contact us if you need more details on Waterjet Glass Cutting Machines. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Water Cut Glass Machine、Waterjet Glass Cutting Machines. If these products fail to match your need, please contact us and we would like to provide relevant information.

Contact us if you need more details on Waterjet Glass Cutting Machines. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Water Cut Glass Machine、Waterjet Glass Cutting Machines. If these products fail to match your need, please contact us and we would like to provide relevant information. Product Categories : Glass Cutting Machine

Premium Related Products

Other Products

Hot Products

Rotary Packing Machine for FoodRoll Feeding Square Bottom Paper Hand Bag Machine1050 Flexo Paper Cup Printing MachinePaper Cup Printing Machine, PE Coated Paper1000*2000mm good price ultra-high pressure rubber cutting machinewater jet cutting machine with 3000mm*2000mm cutting table and 380Mpa intensifier pumpManufacturer water jet cutting pump intensifier pumpfor cutting composite material 1500*3000mm by CNC high pressureCE glass CNC water jet cutteraluminum cutting aluminium cutter machine aluminium sheet cutting machineCE certificate CNC waterjet glass cutting machine /waterjet cutter for glasscnc glass cutting machine price glass waterjetCNC marble mosaic cutting machine with competitive price tile cutting machine1500*2500mm cnc cantilever type marble and ceramic tile medallion waterjet cutting machine1500*2500mm cnc cantilever type stone cutting machine1500*2500mm portable water jet cutting machine for gas tube