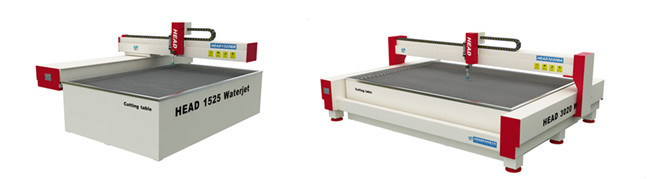

on sale water jet Intricate Industrial Parts cutting machine factory

| Payment Type: | L/C,T/T |

|---|---|

| Min. Order: | 1 Set/Sets |

| Delivery Time: | 30 Days |

| Packaging: | soft packing or according to your request. |

|---|---|

| Brand: | HEAD |

| Place of Origin: | Liaoning, China (Mainland) |

| Supply Ability: | 15 Set/Sets per Month |

Basic Info

Model No.: HEAD1525BB/HEAD42037Z

Product Description

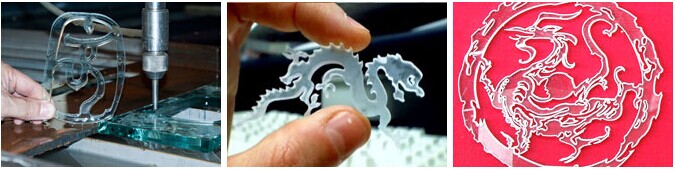

glass cutting samples (click website link)

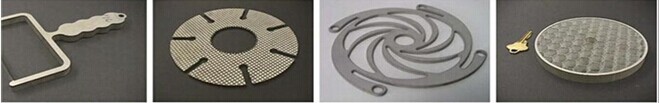

glass cutting samples (click website link)  metal cutting samples (click website link)

metal cutting samples (click website link)  cermaic marble cutting sample (click website link)

cermaic marble cutting sample (click website link)  Main Technical data.

Main Technical data. intensifier pump |

| HEAD38030Z |

| HEAD42037Z | ||||||

| Main technical data | |||||||||

Intensifier brand | from American | |||||||||

Reversing way | Electrical shift | |||||||||

the range of pressure | is 50-420MPa | |||||||||

Max discharge of oil pump | 90L/min,106L/min | |||||||||

Max water discharge | 3.7L/min,3.8L/min | |||||||||

Max orifice diameter | 0.3mm.0.33 | |||||||||

Main motor power | 30KW(25Hp)-37KW(50Hp) | |||||||||

Power supply | 380V/50HZ | |||||||||

CNC System | Main characters | |||||||||

| Controller | CNC control | ||||||||

Size of LED | 19 Inch LCD | |||||||||

File type | DXF file | |||||||||

Computer | industrial professional computer | |||||||||

operation system | Windows XP | |||||||||

advantage of cutting software | autosave and transfer common cutting parameter | |||||||||

Controller displace | controller can be fit to suitable place at will. | |||||||||

| ||||||||||

cutting table | ||||||||||

Processing scope | ||||||||||

1500mm×2500mm | 2000mm×3000mm | 2000mm×4000mm | 3000mm×2000mm | 2000mm×6000mm | ||||||

Main characters | ||||||||||

X beam material | one-off extrusion forming aluminum alloy | |||||||||

Drive system | Z-axis auto control, has 3-axis linkage control and auto tool setting function. | |||||||||

ball screw and linear guide | ABBA from TAIWAN | |||||||||

Platform structure | separated structure | |||||||||

Drive system | Servo drive | |||||||||

Main technical data | ||||||||||

Z-axis journey | 150mm | |||||||||

Control accuracy | ±0.01mm | |||||||||

Cutting accuracy | ±0.1-0.2mm | |||||||||

Max thickness | 100mm | |||||||||

Optional parts | ||||||||||

Dynamic cutting head(4-axis) | It will make no inclination available, improve cutting quality, can be used in stone and ceramic medallion, which makes them avoid polishing and increase efficiency. At the same time , it will improve medallion level. | |||||||||

Auto water cycle cooler | It is used for cooling the water temprature, to insure the hydraulic oil at suitable temprature and the equipment in normal operation. | |||||||||

Usage | Glass, marble medallion, stone medallion, ceramics medallion, metal, brass, titanium, rubber, foam, bamboo, stainless steel, crystal, automotive carpet, fabric, granite and so on. |

To ensure high quality machine, we choose international famous brand partner,

To ensure high quality machine, we choose international famous brand partner,  Certificate We got CE and ISO certificate. We can supply best machine quality and best service for you.

Certificate We got CE and ISO certificate. We can supply best machine quality and best service for you.  Packaging & Shipping

Packaging & Shipping  HEAD waterjet cutting machine: Soft packing, by sea, any port , safe and reliable! Our machine has been exported to 28 countries: Asia :Vietnam, Sri Lanka, Malaysia, Philippines ,Iran, Thailand,UAE ,Qatar ,Iraq

HEAD waterjet cutting machine: Soft packing, by sea, any port , safe and reliable! Our machine has been exported to 28 countries: Asia :Vietnam, Sri Lanka, Malaysia, Philippines ,Iran, Thailand,UAE ,Qatar ,IraqEurope:Russia ,Austria,Latvia,Finland,Germany , Switzerland, UK ,Ukraine ,Romania

America:USA ,Brazil ,Argentina ,Ecuador,Chile , Mexico, Canada.

Africa :South Africa ,Algeria Oceania:Australia Our Services

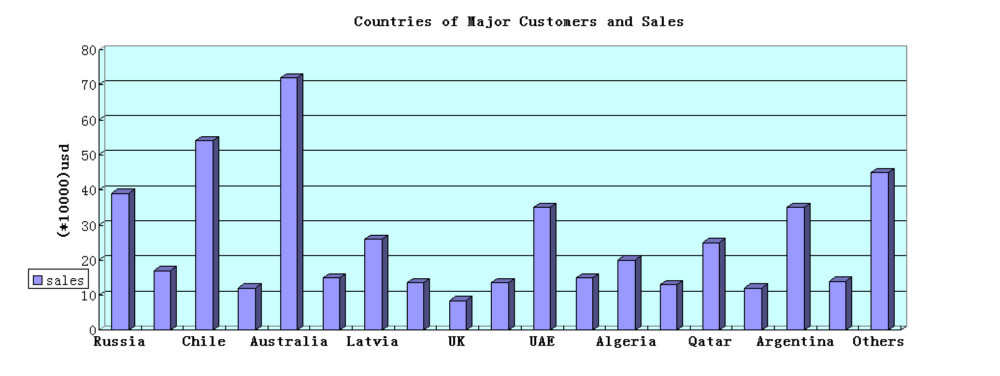

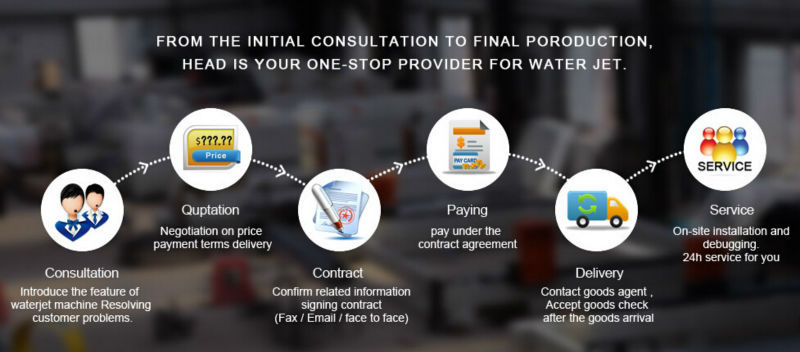

Overseas service is avaiable. Our engineers will help you install and commision in your factory. 7 days per week, 24 hours per day, We are all here for you. Technical Training: 1. UHP Intensifier principle 2. Introduction of every parts 3. Wear parts replacement 4. Elimination of normal troubles 5. Table maintenance 6. On-off valve, cutting head and abrasive controller maintenance. 7. Drawing designing and programming 8. Software operating, parameters setting and saving 9. Equipment operating Any place, any time, you need us, our after-sales service will be there. Sales Amount Our machine has exported to 28 countries and get rich experience including production, overseas after-sales service etc, please check our sales amount of 2013. We are confident that we will supply best machine and services to you.

Overseas service is avaiable. Our engineers will help you install and commision in your factory. 7 days per week, 24 hours per day, We are all here for you. Technical Training: 1. UHP Intensifier principle 2. Introduction of every parts 3. Wear parts replacement 4. Elimination of normal troubles 5. Table maintenance 6. On-off valve, cutting head and abrasive controller maintenance. 7. Drawing designing and programming 8. Software operating, parameters setting and saving 9. Equipment operating Any place, any time, you need us, our after-sales service will be there. Sales Amount Our machine has exported to 28 countries and get rich experience including production, overseas after-sales service etc, please check our sales amount of 2013. We are confident that we will supply best machine and services to you.  Company Information Our company integrate in Research&Development, production,overseas after-sales service, our professional team will give you satisfied high quality machine and service.

Company Information Our company integrate in Research&Development, production,overseas after-sales service, our professional team will give you satisfied high quality machine and service.  company culture

company culture  FAQ WHY CHOOSE US? 1. High quality The components we use is from high level suppliers, which can guarantee the stable working and long life use time. The no troubleshorting working time can be over 1000 hours Can guarantee the cutting accuracy 2. Easy operation Professional Water Cutting Machine software, no need G code program, you only need to know the use of AUTOCAD 3. New function development We work to develop new products to update the function of machine, for short time, we reserch the loading system, height tracking system, wireless handle, four-axis cutting head. 4. Favorable spare parts price and supply on time. When your machine need spare parts to work, we will act quickly, and guarantte the machine work continuously. 5. After sale service Professional service team and 24 hours online to solve your problems, give quick and professional guide. Our all team will do our best to give you a satisfied customer experience. Thanks for your viewing our product. Contact us if you need more details on Water Jet Intricate Industrial Parts Cutting Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Water Jet Intricate Industrial Parts Cutting Machine、Water Jet Intricate Industrial Parts Cutting Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

FAQ WHY CHOOSE US? 1. High quality The components we use is from high level suppliers, which can guarantee the stable working and long life use time. The no troubleshorting working time can be over 1000 hours Can guarantee the cutting accuracy 2. Easy operation Professional Water Cutting Machine software, no need G code program, you only need to know the use of AUTOCAD 3. New function development We work to develop new products to update the function of machine, for short time, we reserch the loading system, height tracking system, wireless handle, four-axis cutting head. 4. Favorable spare parts price and supply on time. When your machine need spare parts to work, we will act quickly, and guarantte the machine work continuously. 5. After sale service Professional service team and 24 hours online to solve your problems, give quick and professional guide. Our all team will do our best to give you a satisfied customer experience. Thanks for your viewing our product. Contact us if you need more details on Water Jet Intricate Industrial Parts Cutting Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Water Jet Intricate Industrial Parts Cutting Machine、Water Jet Intricate Industrial Parts Cutting Machine. If these products fail to match your need, please contact us and we would like to provide relevant information. Product Categories : Flying Arm Cutting Machine

Premium Related Products