machine for ceramic automatic cnc waterjet ceramic cutting machines

| Payment Type: | L/C,T/T |

|---|---|

| Min. Order: | 1 Set/Sets |

| Delivery Time: | 15 Days |

| Packaging: | cnc waterjet ceramic cutting machines soft packing or according to your request. |

|---|---|

| Brand: | HEAD |

| Place of Origin: | Liaoning, China (Mainland) |

| Supply Ability: | 15 Set/Sets per Month cnc waterjet ceramic cutting machines |

Basic Info

Model No.: HEAD42037Z

Product Description

Product Description

Product Description

Main technical parameter of waterjet Cutting Machine | ||

Intensifier Pump | Item | Parameter |

| Model | HEAD42037Z |

Brand | Imported from USA | |

Shift Mode | Electronic Direction Regulation | |

Pressure Range | 420MPA | |

Max Flow of Hydraulic Pump | 106L/min | |

Max Discharge Capacity | 3.8L/min | |

Max Diameter of Gem Nozzle | 0.35mm | |

Power of Master Motor | 37KW(50Hp) | |

Power Source | 380V/50HZ | |

Cutting Table | Item | Parameter |

| X axis characteristic | Adapting the one-off extrusion forming aluminum alloy |

Y axis characteristic | Cast iron used as foundation base | |

Z axis characteristic | Z axis double linear guide and four sliding block | |

Driving system | Z axis automatic controll,3 axis association processing | |

Ball screw,linear guide | ABBA Taiwan | |

Table structure | Separated body | |

Driving way | Servo drive system | |

CNC system | Ncstudio ,Fagor | |

Servo motor | YASKAWA/FUJI | |

Cutting head | Casting structure and concrete structure | |

Sealing way | Whole piece sealing,cancelling dustproof cloth on X,Y,Z axis | |

Loading weight water tank | Wall thickness is 5mm,using fluorocarbon coating | |

CNC Controller | Item | Parameter |

| Control Method | CNC |

Display Size | 19inch LCD | |

Model of Cutting Text | DXF | |

Model of Computer | Industrial Control Computer | |

Operating System | Windows XP/7 | |

PLC | OMRON | |

Cutting software advantage | Auto save and transfer common parameter | |

Controller displace | Can be fit to suitable place at own will | |

Automatic Abrasive Feeder | Item | Parameter |

| Founction | Sand storage and sand delivery |

Operating | No need electrocnic control,sample operation | |

Capacity | 200 liters for 8 hours | |

Pressure | Less than 0.2Mpa compresses gas pressure | |

Level | Standard equipment of HEAD waterjet | |

Color | White | |

Deionization System | Item | Parameter |

| Water pressure | 0.15Mpa~0.6Mpa |

Water temperature | 5°C~50°C | |

Environment temperature | 5°C~50°C | |

Relative humidity | ≤95%(25°C) | |

Water turbidity | <20FTU | |

Wireless Handel | Item | Parameter |

| Founction | Wireless controlling waterjet |

Display | Real- time display condition of X,Y,Z axis | |

Settings | Zero point, on/off valve set, X,Y,Z axis moving | |

Technology | Advanced technology | |

Inspeciton To ensure HEAD Waterjet Cutting Machine can run well, our technicians have made a series of strict inspection before shipping, we use the most accurate and advanced testing tools so that HEAD Waterjet Cutting Machine can reach the internatioal standard to meet the demands of different customers.

Inspeciton To ensure HEAD Waterjet Cutting Machine can run well, our technicians have made a series of strict inspection before shipping, we use the most accurate and advanced testing tools so that HEAD Waterjet Cutting Machine can reach the internatioal standard to meet the demands of different customers.  Our Services Engineers available to service machinery overseas for cnc waterjet ceramic cutting machines Technical Training: 1. UHP Intensifier principle 2. Introduction of every parts 3. Wear parts replacement 4. Elimination of normal troubles 5. Table maintenance 6. On-off valve, cutting head and abrasive controller maintenance. 7. Drawing designing and programming 8. Software operating, parameters setting and saving 9. Equipment operating

Our Services Engineers available to service machinery overseas for cnc waterjet ceramic cutting machines Technical Training: 1. UHP Intensifier principle 2. Introduction of every parts 3. Wear parts replacement 4. Elimination of normal troubles 5. Table maintenance 6. On-off valve, cutting head and abrasive controller maintenance. 7. Drawing designing and programming 8. Software operating, parameters setting and saving 9. Equipment operating  Packaging & Shipping HEAD Corporation : cnc waterjet ceramic cutting machines soft packing, by sea, any port , safe and reliable!

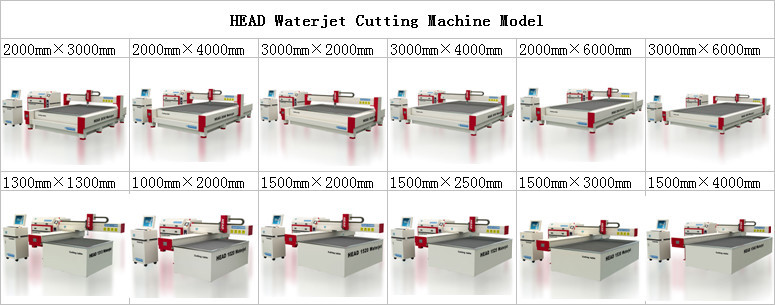

Packaging & Shipping HEAD Corporation : cnc waterjet ceramic cutting machines soft packing, by sea, any port , safe and reliable!  we have more than 20 kinds of models, welcome to your more details inquiry !

we have more than 20 kinds of models, welcome to your more details inquiry !  Contact us if you need more details on Cnc Waterjet Ceramic Cutting Machines. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Machine for Ceramic、Waterjet Ceramic Cutting Machines. If these products fail to match your need, please contact us and we would like to provide relevant information.

Contact us if you need more details on Cnc Waterjet Ceramic Cutting Machines. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Machine for Ceramic、Waterjet Ceramic Cutting Machines. If these products fail to match your need, please contact us and we would like to provide relevant information. Product Categories : Ceramic Cutting Machine

Premium Related Products